Lithium-Ion Recycling

Enabling the circular economy for Lithium-Ion batteries.

Ecobat Solutions processes end-of-life, damaged and production scrap lithium-ion (LIB) batteries into recoverable Black Mass and recyclable content streams. Black Mass is the separated electrode active materials from a lithium-ion battery, and is the output stream containing nickel, cobalt and lithium. Recovering these critical materials enables an on-shore closed loop battery material recycling ecosystem, reducing supply chain cost and environmental impact and providing an alternate source of these materials from unsustainable mines.

At its heart, Ecobat is a materials recovery business. To succeed, as in any other commodity business, Ecobat has developed a low-cost, high efficiency process to offer the most competitive rates for recycling. But cost is only one factor of advanced battery recycling; safety and risk management are two other pillars Ecobat operates by. Safety of its employees, customers, and surrounding communities comes first and foremost, and Ecobat takes pride in innovating new, safe techniques and best practices to minimize impact to each of these stakeholders.

Ecobat operates three lithium-ion recycling plants today in the US and Europe: Casa Grande, Arizona; Hettstedt, Germany; and Birmingham, England. These plants represent the first phase of Ecobat’s lithium recycling footprint and are sized to adequately serve their respective markets for the next several years.

Ecobat Solutions can solve lithium-ion battery recycling for your specific needs. Whether its high-risk, damaged batteries, undischarged power tool and consumer batteries, or even full-size EV batteries, Ecobat can provide logistics and recycling services at competitive rates. Use our form to make an inquiry today.

Who we serve.

Ecobat serves the full range of lithium-ion scrap generators; from battery cell manufacturers generating production scrap all the way to end-of-life EV batteries recovered from scrap yards, Ecobat is open to working with you to solve your lithium-ion recycling needs.

Ecobat is ready to make competitive offers for your scrap lithium-ion batteries. Whether your business has been collecting batteries for years or you’re just getting into it, Ecobat can provide battery disposal and recycling services to ensure compliance, safety and highest value returned.

Ecobat handles all types of lithium-ion scrap. Whether you’re dismantling an EV, or collecting batteries from consumer devices or power tools, Ecobat can offer you a convenient and valuable lithium recycling service.

New to lithium-ion batteries? Contact us to understand what your options are. Ecobat can help you decide how to invest in lithium-ion safety devices, as well as provide battery removal, pick up and collection options for your convenience.

You are experts at e-waste value recovery. Let Ecobat offer you maximum value for your battery scrap. Are you mixing batteries with other components for a bulk scrap payable? Increase the value of both streams by separating the lithium-ion material and sending it to Ecobat. We are experts at maximizing the value of your scrap.

As more and more applications shift to battery powered electrification, critical applications require backup power and UPS, and electrification takes hold in general, the amount of batteries ITAD and e-waste recyclers are forced to handle will increase exponentially. Having a strong partner for the offtake of these hazardous materials is critical to ensuring the maximization of value from your recycling efforts, as well as the appropriate risk and battery lifecycle management of these materials.

We are able to offer competitive rates across all types and chemistries of lithium-ion batteries, including cell phones, laptops, power tools, e-bike and other common batteries. Our team of researchers have identified common trends that give us accuracy of chemistry based on format, so you can be assured that our offer is fair.

EVs and Hybrids are making a huge impact on operating costs for fleets of all sizes. However, total cost of ownership must include lithium-ion recycling and disposal costs for the EV and hybrid batteries themselves. With the wide range of chemistries and values in the market today, Ecobat can help give your fleet the lowest TCO by making competitive bids specific to the EV and hybrid batteries and vehicles you are retiring for remanufacturing.

Government fleet or an operator with municipal and government contracts? Ecobat’s domestic battery recycling program meets the criteria for IRA and BIL compliance. All lithium-ion material that is sent to Ecobat is recovered in the US. Ecobat is recycling valuable Lithium, Cobalt and Nickel on-shore to be reused in new advanced batteries. This is at the core of Ecobat’s business. At the same time, shortening supply chains can help your business: shorter lead times, lower costs and a reduced regulatory risk profile are all value-additions that Ecobat can contribute to your EV and hybrid fleet.

Renewable energy projects rely heavily on backup storage, and lithium-ion technology presents great ESS recycling opportunities to extend lifetimes, reduce operating costs and improve performance. However, proper planning and care must be taken during the decommissioning phase to avoid undue cost and compliance issues when it comes to recycling BESS installations. As LFP becomes more common, proper consideration must be given to the low value of the recovered material in LFP recycling. Ecobat is happy to quote and work with BESS operations to reduce the TCO and improve their end of life economics.

The first lithium-ion BESS installations are already nearing their end of life. These early facilities probably use a valuable cathode chemistry which Ecobat and other recyclers are happy to make competitive offers for. However, newer BESS installations typically use lithium iron phosphate (LFP) cathode chemistry. While far less expensive to manufacture, there is very little residual material value in these batteries due to the lack of cobalt and nickel. Ecobat specializes in the efficient recovery of all materials, including copper, aluminum, steel and lithium – each of which is contained in LFP battery packs. And because Ecobat is an independent recycler, we are not obligated to fill a refinery full of nickel and cobalt. That means that Ecobat is ready and willing to give you a fair, cost-based price to recycle your LFP scrap material.

Ensuring your scrap is bound for ESS recycling and material recovery is vital in maintaining a healthy ESG profile and your brand’s reputation. Because of the low value of LFP, some “battery disposal” agencies may send these batteries intact overseas for cell harvesting. That means your scrap battery material may end up in a new application without your knowledge or permission. Ecobat is committed to recycling and can provide evidence and documentation that your batteries have been recycled.

Whether your business manufactures cells or assembles modules and packs, Ecobat can alleviate your production scrap as well as return value from your customer’s battery end-of-life materials you may be responsible for. Capable of handling all cathode chemistries, including NMC recycling, NCA recycling, LFP recycling and LMO recycling, Ecobat is your one stop shop for recycling.

Have access to scrap material and unsure of what to do with it? Let Ecobat offer a quote. We can liberate electrode material from wet and dry scrap, and it does not have to contain cathode material. Ecobat can handle all formats including cathode and anode trimmings, electrode powder, stacked or layered foils, wet cells, dry cells and rejected modules.

Because Ecobat recycles domestically, there is no risk of IP leakage or brand reputation erosion. Unlike Ecobat, some “battery disposal” agencies may send intact batteries overseas for cell harvesting. That means your scrap battery material may end up in a new application without your knowledge or permission. Ecobat is committed to recycling and can provide evidence and documentation that your batteries have been recycled.

Ecobat works with global OEMs to recycle batteries. We are able to manage battery recall work, prototypes, end-of-life and damaged packs. Chemistry and format are no issue with Ecobat, nor is state of charge. We can handle everything from modules and hybrid packs through high density cell to pack designs. Contact us to see how competitive Ecobat can be for your scrap lithium-ion batteries.

Whether you have prototypes that require safe disposal for IP protection, warranty replacement packs that must be taken out of the off-network ecosystem, or simply damaged or end of life batteries, Ecobat has a solution for you. We are able to maximize value while maintaining the highest standards of safety and environmental responsibility. We offer several types of commercial options, including tolling, net payables for nickel and cobalt, and processing charges for other scrap.

Why Ecobat?

Cost

Ecobat offers competitive rates for lithium-ion recycling. Our process is designed for efficiency, yield and low operating costs. Designed in-house, Ecobat is the only company to operate this setup. Through continuous improvement, Ecobat maintains margin through lowering cost and winning new business- a key to a sustainable recycling partner.

Sustainability

Ecobat’s proprietary process relies exclusively on mechanical separation. There is no costly and high emission drying or calcination stage, making Ecobat’s scope 1 & 2 emission portfolio impressively low. Ecobat’s first US location in Arizona presents multiple advantages: as an electric process, low cost and sustainable energy is prolific in the area; a naturally warm and dry environment yields low moisture Black Mass; low logistics burden from several high-density locations in the American West.

View Our 2023 Sustainability ReportSafety & Compliance

Ecobat prioritizes the health and safety of its employees, customers, and communities by designing facilities with state-of-the-art emissions controls and environmental monitoring to minimize risks. With decades of experience in managing lithium-ion thermal events and numerous protective measures, Ecobat complies with all regulations for safe recycling and handling hazardous waste. The company proactively collaborates with regulators, fire departments, and other stakeholders to address the challenges of lithium-ion safe battery disposal.

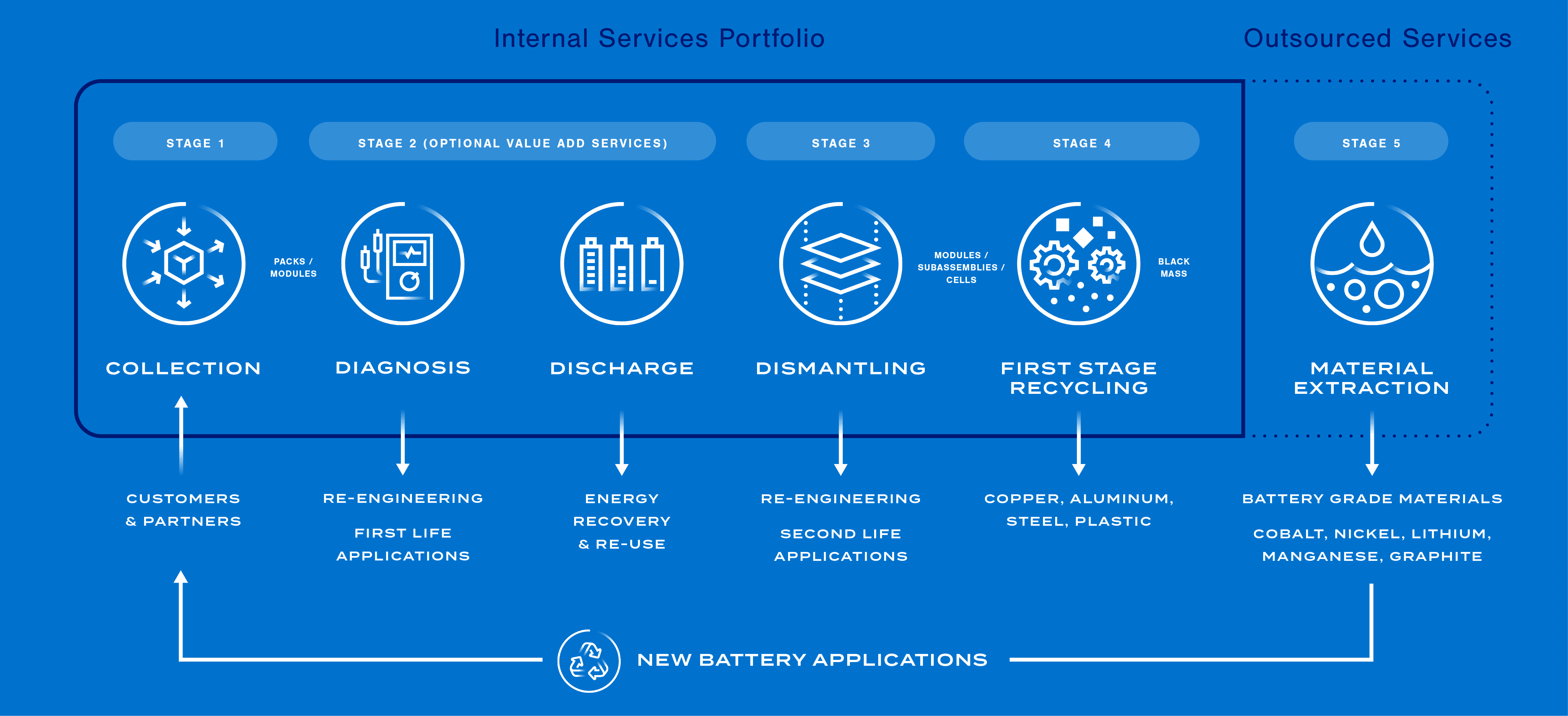

Our lithium recycling process.